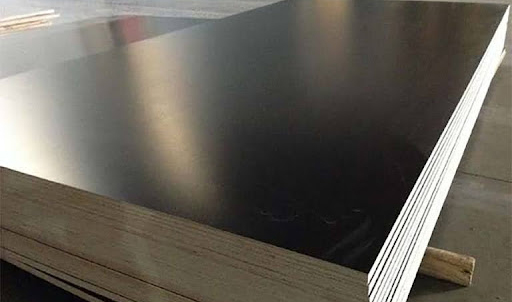

Film faced plywood is one of the most popular used formwork today and specifically designed for shaping concrete blocks to ensure that the concrete blocks are solid

Manufacturers usually join many layers of wood together with specialized, water-resistant glue. This makes the board waterproof and resistant to significant external force without deformation.

2 – Specifications

| Property | Specifications |

| Size | 1220x2440mm,910x1830mm,610x2440mm,or customize |

| Thickness | 12mm, 15mm, 18mm, 21mm or customize |

| Tolerance | +/-0.5mm |

| Face/Back | Plain Black/Brown/Red-Film, Logo Film |

| Glue Type | Melamine 12%-25%, Phenolic |

| Density | 600-700 kgs/m3 |

| Maximum moisture | 12% |

| Layer separation force | 0.75–1.5 Mpa |

| Reuse | 4-6 times, 8-12 times, 15-20 times, 20-25 times |

3 – Advantage:

Film faced plywood is commonly used in the field of construction and construction,… thanks to outstanding advantages in terms of performance compared to other materials

| ✅ Low deformation, keep a stable shape after long time use. | The wood reinforcement of film faced plywood with a structure of many layers of thin laminated wood combined with specialized glue increases the cohesion of the board. Normally, the number of layers of veneer in a film faced board is usually an odd number such as 3, 5, 7,… with a central layer that helps the board balance the force. As a result, this type of wood has extremely good bearing capacity, is less prone to shrinkage and warping after a long time of use, and is often used as a concrete pouring mold in high-rise buildings, etc |

| ✅ Good water and heat resistance even in harsh environments. | Producers use waterproof BWP glue to make Vietnamese film-faced plywood, ensuring the board has superior water resistance. Testing shows that the film-faced plywood can endure a 72-hour boiling process without separating. Additionally, they maintain the board’s moisture content at an ideal 12%. As a result, the formwork resists water, heat, and mold even in harsh environments. |

| ✅ Easy to apply. | Vietnamese Plywood and especially film faced plywood are often compatible with machines, good screw adhesion makes construction and installation easier. With a lighter weight than other materials such as iron and steel or natural wood, the transportation of formwork is also light and saves construction time. |

| ✅ Reasonable cost, high reusability. | When assembling the formwork, the film faced boards form a closed surface, fixing the concrete inside, avoiding material loss due to molten cement. Thanks to the smooth film, this concrete surface after dismantling the beautiful flat formwork, can roll the paint directly without additional treatment, shortening the construction time. Vietnamese film faced Plywood receive feedback from customers that they are reusable up to 20 times. Thus, contractors and investors can be completely assured of the quality of the work and still optimize the cost problem. |

| ✅ Safe for health & Environmentally Friendly. | To ensure this, our rigorous manufacturing process is based on CARB P2 and TSCA Title VI standards. These are standards set to control the amount of Formaldehyde emissions that affect human health as well as the environment.

In addition, the source of raw wood harvested from planted forests is licensed, limiting the use of natural wood, affecting the ecosystem. Accordingly, high-quality formwork at Vietnamese Plywood both meets the criteria of human health and protects the living environment. |

4 – Film faced plywood and its great uses

With a tight structure, film faced plywood possesses outstanding characteristics and features that are difficult to compare with other types of industrial boards. In recent years, this type of plywood has had a solid “foothold” and is widely applied in construction, life and industry,…

Construction

With various advantages such as outstanding water resistance, high mechanical hardness, light weight,… film faced panels are usually used as formwork in construction projects. Using this type of formwork reduces both costs and time.

With various advantages such as outstanding water resistance, high mechanical hardness, light weight,… film faced panels are usually used as formwork in construction projects. Using this type of formwork reduces both costs and time.

In addition, workers can also take advantage of formwork to make temporary houses for living and resting right on the construction site. Due to the advantages of being sturdy and water resistant, they can meet the needs of long-term use.

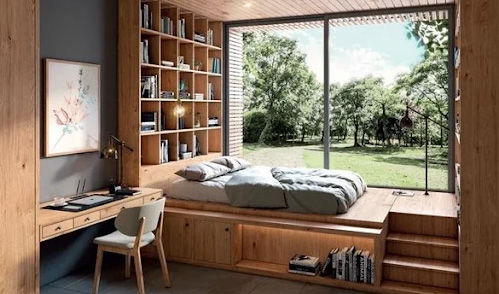

Exterior – interior

Aside from excellent uses in buildings, film faced plywood is also popular in interior and exterior design. Products made from this sort of board can be used in environments that require pressure resistance and high humidity.

Aside from excellent uses in buildings, film faced plywood is also popular in interior and exterior design. Products made from this sort of board can be used in environments that require pressure resistance and high humidity.

Flooring

Another ideal application of higher quality film faced plywood is flooring, which is often seen as lining the floor of trunks, passenger car undercarriages, etc. The glossy surface, good water resistance, and rarely scratched surface are the outstanding advantages of film boards for this purpose.

Another ideal application of higher quality film faced plywood is flooring, which is often seen as lining the floor of trunks, passenger car undercarriages, etc. The glossy surface, good water resistance, and rarely scratched surface are the outstanding advantages of film boards for this purpose.

5 – Instructions for proper use and storage of formwork

Proper storage and use of film plywood is important, contributing to increasing the service life. To help consumers optimize construction costs, we offer some things to note as follows:

Before Use

- Store the film board in dry places, away from direct sunlight horizontally.

- When moving, it is necessary to fasten the bale belt firmly, avoiding dropping leading to damage to the board and ensuring the safety of workers.

- Using a lifting machine helps to limit surface scratches to the maximum, avoiding dragging along the board on the floor.

When to use

- Use saws and cutters with sharp, sturdy blades to limit breakage of the board structure, ensuring labor safety.

- A layer of duct tape should be applied to the surface to limit cracking when drilling or screwing.

- After cutting, the edge of the film-coated formwork needs to be coated with water-repellent glue to avoid the penetration of termites.

- Use mold oil, anti-adhesion agent before pouring concrete to make cleaning afterwards easier, reducing damage to the board surface.

After Use

- Use water jets and plastic/plastic brushes to clean the formwork plywood to limit surface scratches

- Allow the board to be dry and clean before taking it to storage.

6 – Exporting countries of Vietnam plywood

Vietnam is one of the 3 largest exporters of film faced plywood in the world, mainly exporting to Korea, Malaysia, USA, Singapore,….

In conclusion,

Above is the sharing of some information about Vietnam’s film-faced plywood, hopefully customers can understand more about this type of industrial wood through this article. If you have any questions, please contact us for further advice and support.